The Ultimate Solution for Composite Material Reinforcement

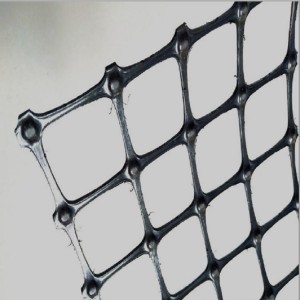

The square or rectangular polymer mesh formed by stretching can be uniaxially stretched or biaxially stretched according to the different stretching directions during its manufacture. It punches holes in an extruded polymer sheet (the raw material is mostly polypropylene or high-density polyethylene), and then performs directional stretching under heated conditions. The uniaxially stretched grid is only stretched along the length direction of the sheet; the biaxially stretched grid is made by continuing to stretch the uniaxially stretched grid in a direction perpendicular to its length.

During the manufacture of the plastic geogrid, the polymer polymers will rearrange and align with the heating and extension process, which strengthens the bonding force between the molecular chains and achieves the purpose of improving its strength. Its elongation is only 10% to 15% of the original plate. If anti-aging materials such as carbon black are added to the geogrid, it can have good acid resistance, alkali resistance, corrosion resistance and aging resistance.

Mine grille is a kind of plastic net for coal mine underground. It uses polypropylene as the main raw material. After being treated with flame retardant and antistatic technology, it adopts the biaxial stretching method to form the overall structure of "double anti" plastic net. The product is convenient for construction, low cost, safe and beautiful

Mine geogrid is also called biaxially stretched plastic mesh false roof for underground coal mines in coal mine work, referred to as false roof net. Mining geogrid is specially designed and manufactured for the false roof support of coal mine mining face and roadway side support. It is made of several kinds of high molecular polymers and filled with other modifiers. , Punching, stretching, shaping, coiling and other processes are manufactured. Compared with metal textile mesh and plastic woven mesh, mining geogrid has the characteristics of light weight, high strength, isotropy, antistatic, non-corrosion, and flame retardant. It is a new type of coal mine underground support engineering and civil engineering. Use mesh grill material.

Mining geogrid is mainly used for the false roof support project of coal mine mining face. Mining geogrid can also be used as soil and stone anchoring and reinforcement for other mine roadway engineering, slope protection engineering, underground civil engineering and traffic road engineering. Material, mine grating is one of the best alternatives to plastic textile mesh.

Friction is not easy to generate static electricity. In the environment of underground coal mines, the average surface resistance of plastic mesh is below 1×109Ω.

Good flame retardant properties. It can respectively meet the flame retardant properties stipulated in coal industry standards MT141-2005 and MT113-1995.

Easy to wash coal. The density of the plastic mesh is about 0.92, which is less than that of water. During the coal washing process, the broken mesh floats on the water surface and is easy to be washed away. Strong anti-corrosion ability, anti-aging.

It is convenient for construction and transportation. The plastic mesh is relatively soft, so it is not suitable to scratch workers during construction, and it has the advantages of easy curling and bundling, mine grid cutting and light specific gravity, so it is convenient for underground transportation, carrying and construction.

Both vertical and horizontal directions have strong bearing capacity. Since this plastic mesh is biaxially stretched rather than woven, the creep of the mesh is small and the mesh size is uniform, which can effectively prevent the falling of broken coal and protect the safety of underground workers and the safety and security of mine workers. The safety of mine car operation.

Application field This product is mainly used for side protection during underground mining of coal mines, and can be used as a support material for bolt roadways, support roadways, anchor shotcrete roadways and other roadways. When used for false roofs, it should be used in conjunction with two or more layers.

The steel-plastic geogrid is made of high-strength steel wire (or other fibers), which is specially treated, and polyethylene (PE), and other additives are added to make it a composite high-strength tensile strip through extrusion, and the surface has rough pressure. pattern, it is a high-strength reinforced geotechnical belt. From this single belt, weaving or clamping arrangement at a certain distance vertically and horizontally, and welding its junctions with special strengthening bonding fusion welding technology to form a reinforced geogrid.

High strength, small deformation

Corrosion resistance and long service life: The steel-plastic geogrid uses plastic materials as the protective layer, supplemented with various additives to make it anti-aging, oxidation-resistant, and resistant to corrosion in harsh environments such as acids, alkalis, and salts. Therefore, the steel-plastic geogrid can meet the use requirements of various permanent projects for more than 100 years, and has excellent performance and good dimensional stability.

The construction is convenient and quick, the cycle is short, and the cost is low: the steel-plastic geogrid is laid, lapped, positioned easily, and leveled, avoiding overlapping and crossing, which can effectively shorten the project cycle and save 10%-50% of the project cost.

Glass fiber geogrid is made of glass fiber and made of mesh structure material by a certain weaving process. In order to protect the glass fiber and improve the overall performance, it is a geotechnical composite material made of a special coating process. The main components of glass fiber are: silica, which is an inorganic material. Its physical and chemical properties are extremely stable, and it has high strength, high modulus, high wear resistance and excellent cold resistance, no long-term creep; thermal stability Good performance; the network structure makes the aggregate interlock and limit; improves the load-bearing capacity of the asphalt mixture. Because the surface is coated with special modified asphalt, it has double composite properties, which greatly improves the wear resistance and shearing capacity of the geogrid.

Sometimes it is combined with self-adhesive pressure-sensitive adhesive and surface asphalt impregnation to make the grille and asphalt pavement tightly integrated. As the interlocking force of earth and stone materials in the geogrid grid increases, the friction coefficient between them increases significantly (up to 08-10), and the pullout resistance of the geogrid embedded in the soil is due to the gap between the grid and the soil. The frictional bite force is stronger and significantly increased, so it is a good reinforcement material. At the same time, geogrid is a kind of light weight and flexible plastic plane mesh material, which is easy to cut and connect on site, and can also be overlapped and overlapped. The construction is simple and does not require special construction machinery and professional technicians.

High tensile strength, low elongation——Fiberglass geogrid is made of glass fiber, which has high resistance to deformation, and the elongation at break is less than 3%.

No long-term creep - as a reinforced material, it is extremely important to have the ability to resist deformation under long-term load, that is, creep resistance. Glass fibers will not creep, which ensures that the product can maintain its performance for a long time.

Thermal stability - the melting temperature of glass fiber is above 1000°C, which ensures the thermal stability of glass fiber geogrid during paving operations.

Compatibility with asphalt mixture - the material coated by fiberglass geogrid in the post-treatment process is designed for asphalt mixture, each fiber is fully coated, and has high compatibility with asphalt, This ensures that the fiberglass geogrid will not be isolated from the asphalt mixture in the asphalt layer, but firmly combined.

Physical and chemical stability - After being coated with a special post-treatment agent, the fiberglass geogrid can resist various physical wear and chemical erosion, and can also resist biological erosion and climate change, ensuring that its performance will not be affected.

Aggregate interlocking and confinement—Because the fiberglass geogrid is a network structure, aggregates in asphalt concrete can run through it, thus forming a mechanical interlocking. This restriction hinders the movement of the aggregate, allowing the asphalt mixture to achieve better compaction under load, higher load-bearing capacity, better load transfer performance and less deformation.

Polyester fiber warp-knitted geogrid is made of high-strength polyester fiber. The warp-knitted directional structure is adopted, and the warp and weft yarns in the fabric have no bending state, and the intersection points are bundled with high-strength fiber filaments to form a firm joint point and give full play to its mechanical properties. High-strength polyester fiber warp-knitted geogrid The grid has high tensile strength, small elongation, high tear strength, small difference in vertical and horizontal strength, UV aging resistance, wear resistance, corrosion resistance, light weight, strong interlocking force with soil or gravel, and is very effective for strengthening soil. Shear resistance and reinforcement improve the integrity and load capacity of the soil, which has a significant effect.

Used to strengthen weak foundations: Geogrids can quickly increase the bearing capacity of foundations, control the development of settlement, and effectively distribute the load to wider subbases by limiting the effect on the road base, thereby reducing the thickness of the base and reducing the engineering cost. Cost, shorten construction period, prolong service life.

Unidirectional geogrid is used to reinforce asphalt or cement pavement: Geogrid is laid on the bottom of asphalt or cement pavement, which can reduce the depth of rutting, prolong the anti-fatigue life of the pavement, and reduce the thickness of asphalt or cement pavement to save costs.

Used to reinforce embankments, dams and retaining walls: Traditional embankments, especially high embankments, often require overfilling and the edge of the road shoulder is not easy to compact, which leads to rainwater flooding in the later stage, and the phenomenon of collapse and instability occurs from time to time At the same time, a gentle slope is required, which occupies a large area, and the retaining wall also has the same problem. Using geogrid to reinforce the embankment slope or retaining wall can reduce the occupied area by half, prolong the service life, and reduce the The cost is 20-50%.

Used to reinforce river and sea embankments: it can be made into gabions, and then used together with grids to prevent the embankment from being washed by sea water to cause collapse. Gabions are permeable, can slow down the impact of waves, prolong the life of dikes and dams, save manpower and material resources, and shorten the construction period.

Used to deal with landfills: Geogrids are used in combination with other soil synthetic materials to deal with landfills, which can effectively solve problems such as uneven foundation settlement and derivative gas emissions, and can maximize the storage capacity of landfills.

Special purpose of one-way geogrid: low temperature resistance. To adapt to -45 ℃ - 50 ℃ environment. It is suitable for poor geology in the north with less frozen soil, rich frozen soil and high ice content frozen soil.

1.What is a geogrid used for?

A geogrid is a geosynthetic material used to stabilize soil. Geogrids have openings, called apertures, which allow aggregate to strike through and provide confinement and interlock.

When should you use geogrid?

Wall Heights that Require Geogrid Soil Reinforcement

Generally, most VERSA-LOK units need geogrid for walls taller than three to four feet. If there are steep slopes near the wall, loading above the wall, tiered walls or poor soils, then even shorter walls may need geogrid.

3.How long does geogrid last?

The PET geogrid has virtually no degradation for an exposure in outdoor environment for 12 months. It can be attributed to the protection of PVC coatings on the surface of geogrid. Based on the exposure testing studies, suitable protections are mandatory for geotextiles to be used in outdoor environment.

4.How long should a geogrid be for a retaining wall?

Geogrid Length = 0.8 x Retaining Wall Height

So if your wall is 5 feet tall you'll want 4 foot long geogrid layers. For small block walls, geogrid is typically installed every second block layer, starting from the top of the bottom block.

主图-拷贝1-300x300.jpg)